Mercury Engineering’s Group BIM Manager Sean Dowd spoke with Irish building magazine recently about the contractor’s investments in BIM. A leader in Digital Construction and a regular at CitA events, Mercury have a broad portfolio of projects on which they are using BIM and are achieving efficiencies while delivering greater value to some of the world’s largest multinational clients.

The Mercury Engineering Group work across a variety of construction sectors at home and abroad: Data Centres (both hyperscale and enterprise), Life Science & Technology, Building Services, Healthcare, and Fire Protection. In 2017, they were Ireland’s leading Specialist Services Subcontractor with a turnover of €600 million, €258 million of this comes from their work in Ireland.

Sean Dowd

From our previous interviews with Mercury Engineering as part of our ‘Leaders in Construction’ interview series, we learned that the largest sector in terms of revenue generation is the hyperscale data centre sector. In the past decade, the contractor has been awarded €1.6 billion in data centre contracts. In order to win such prestigious contracts, a company must be innovative and competitive, have a culture of continuous improvement and be willing to invest in people, technology and processes. Mercury’s Twenty21 mission requires the company “to continuously adopt better practices, improve corporate structure and focus on building momentum in what is an increasingly competitive construction market”. Mercury’s investment in BIM is helping the contractor meet these requirements.

BIM is in demand by clients in all the sectors in which Mercury work at home and abroad. BIM is especially a prerequisite requirement with datacentre, semiconductor and pharma clients. But that said, the Mercury Engineering Group uses BIM on the vast majority of their projects. This has brought efficiencies to the contractor and greater value to the clients. Investing in their BIM personnel, facilities, hardware and delivering continuous training and upskilling, Mercury ensures that they stay among the international leaders in Digital Construction.

Group BIM Manager Sean Dowd tells us that Mercury Engineering are heavily invested in BIM, having one of the largest BIM teams in Ireland and the UK. “We currently have approximately 130 BIM personnel located in multiple countries including Ireland, the UK, Denmark, the Netherlands, Germany and Poland. However, you need more than a great BIM team to be a leader in Digital Construction – to best serve clients, a variety of training programmes, systems and procedures are required and you need the best facilities and equipment.”

Investments in Facilities, Hardware & Software

Mercury are not just investing in their people, they have invested in new facilities and equipment, most recently in their new BIM Hub in Maynooth and also in offices and sites abroad Sean tells us. “Mercury have invested in a new modern BIM Hub office in Maynooth, County Kildare from where we centrally manage BIM across multiple projects. Our central BIM Hub is strategically located close to many of our large multi-national clients in Ireland. We have a purpose built Virtual Reality (VR) lab in our new offices and have plans to deploy VR rooms into our larger projects. We have invested in both hardware and software to ensure we have the best tools to enable a fast turnaround time at the highest possible quality.” Mercury’s facilities at home and abroad are impressive and Sean gives us some more detail on their resources. “These new offices have two main BIM modelling floors, offices, state of the art meeting rooms, VR labs and a large rest and recuperation area. We also have modern offices in Glasgow and Poland; with smaller satellite offices at client sites.” Surveying is also incorporated into the BIM remit; again they have invested heavily in both hardware and software to increase the speed of surveying, subsequent data processing and cloud access.

Mercury’s BIM Team

Sean tells us more about the experienced BIM team and its pyramid structure. “Our BIM team are highly skilled 3D modellers, with primary focus on Revit, Navisworks, Solibri and CAD based products. Our team are organisationally built around a standard pyramid structure where I, as the Group BIM Manager have seven sector managers. These sector managers have multiple team leads in place with downstream teams of senior modellers, modellers and BIM engineers. We also have a team of systems personnel to build projects from the ground up in Autodesk BIM 360, Glue, Team etc.”

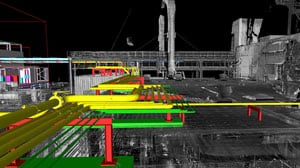

Another key part of the BIM team is their surveyors Sean says. The use of surveying data has become an integral part of the BIM process in Mercury over the past number of years and they have cultivated their own in-house expertise to capture and manage this information. “We have developed systems and procedures to inform the management of our survey work and utilise a combination of proprietary, open source and bespoke software applications to make use of this data. The use of 3D laser scanning and imaging technologies to capture as-is conditions prior to modelling provides an accurate representation of the field conditions through which to route our services. This allows us to actively avoid clashing due to construction misalignment during the modelling process. Owing to the nature of our work, this approach holds for both new build as well as retrofit projects.”

The same technology is used extensively to capture their own install and to produce both deviation analysis reports using dedicated software which can be fed into their construction Quality Assurance systems and handover documentation, and detailed information to allow for accurate redlining of their modelled content. “Where more accurate spatial data is required, such as for service connections, we also employ total stations to deliver spatially accurate tie-in points to our modellers,” Sean adds.

Training & Collaboration

Mercury have had no major challenges implementing BIM on international projects as they are using the cloud, where people can access models from anywhere Sean explains. “With the advantage of BIM in the cloud, we don’t see any real difference between local projects versus international projects. We will generally have a core team based at the client site backed up with personnel at our central Hub, with seamless transitions between both.” Mercury started to used BIM 360 Team in July 2017 and have moved all BIM projects from using local Revit servers to using the Autodesk Cloud service.

Implementing BIM on sites and working with other contractors and designers can be challenging at times but contractors and designers are now engaged with BIM within their own organisations which allows for easier collaboration. “Typically, Revit is the standard platform for all levels of engagement so it is a standard playing field,” Sean states.

Efficiencies & Cost Savings

Returning to the topic of cloud hosting and efficiencies, Sean tells us Mercury have gained efficiencies in time, cost and space using Autodesk’s BIM 360 Platform and AEC Collection. “Within the Mercury BIM Department we utilise BIM 360 Team, BIM 360 Design, Docs, Field, Project Management and Glue. We also use Leica TruView Enterprise to share 3D scan information with site teams and clients.

These products give us cloud based hosting and collaboration across the various geographical sites in which we work. This enables detailers and engineers at our central BIM Hub in Ireland execute and deliver BIM to projects which traditionally would required a team of BIM personnel to be located on site, giving us efficiencies in time, space and ultimately cost. The BIM 360 and AEC Collection also enables other project stakeholders to collaborate with the BIM team, this ensures a common documentation platform and data collection protocol with Docs and Field. Whilst Team, BIM 360 Design and Glue allow the model detailing coordination team to work in parallel and share in real time with project construction teams. Our subscriptions to AEC suites ensure that we have the latest software tools, with all the productivity gains associated to them.”

The industry sees the efficiencies that Mercury achieves, their competitive edge, and the value they are capable of delivering to clients and Sean says they take pride in having the right people, tools and in-house expertise to deliver projects to high standards. “We are seeing competitive edge benefits, through the industry’s view of our efficiency – primarily in our efficient work processes, procedures, standardisation and deliverables. Overall this is something we take great pride in as a department, to us it’s just doing good business. By having the right tools, people and expertise to do this business gives us the competitive edge.”

Positive Feedback

The feedback from Mercury staff members is critical to the Mercury BIM Department, helping to mould their continuous improvement and increase the value delivered to customers. “The BIM Department is part of a very competitive organisation. We take all feedback as constructive feedback and try to put changes in place as rapidly as possible to increase our efficiency for our internal downstream customers. Within the BIM Department we also take inputs on board from our BIM personnel as industry experience provides invaluable insights and quickly generates new ideas and process improvements.”

The feedback from main contractors, designers and clients has been overwhelmingly positive, which is a testament to the changes Mercury are making and the strategic direction they are following. Sean believes in continuous improvement. “As is always the case, there is room for improvement and we take all feedback as another means of improving our systems and processes under our customer and results orientation values.”

BIM Goals & Objectives

Investing in people, facilities, software and hardware, Mercury strive for continuous improvement, they are determined to lead the way in Digital Construction; this is obvious when Sean outlines their BIM goals and objectives for the coming years. “Our goals and objectives are very straight forward: To establish the Mercury BIM team as the No. 1 BIM team in Ireland / UK and in Europe – BIM being the key differentiator enabling Mercury Engineering to win more contracts with new and existing clients; Being seen within the industry as the go-to BIM team for quality and cost; Being the BIM team that the hottest BIM talent wants to be part of in Ireland and in Europe.

“To ensure these objectives are met we will continue to invest in our people through training and upskilling, will provide the latest innovations in tools and software, we will provide the best facilities and ensure our team always feel valued. Ultimately we will continue to listen to our customers’ feedback – both internal and external to Mercury Engineering – taking this feedback on board in a positive manner, with the big goal of being the No. 1 BIM team in the industry.”