Murphy Surveys utilises BIM to provide clients with a new level of advanced data capture.

As early adopters and supporters of laser scanning technology, Murphy Surveys remain at the forefront of innovation, commissioning the latest digital tools to accurately capture comprehensive 3D point cloud data and recording reality with extraordinary detail, regardless of the type of project.

Figure 1 – Leica ScanStation P40

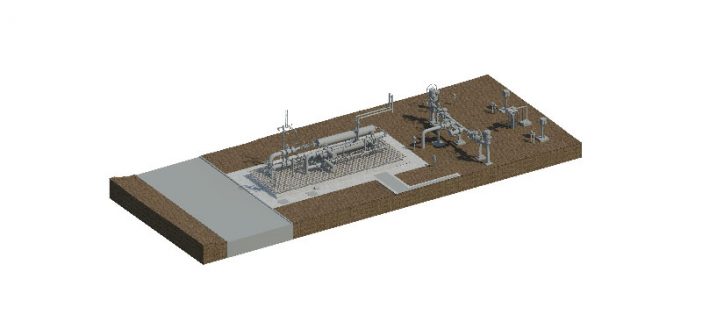

Over the past decade, Murphy Surveys have been digitizing above and underground gas installations for Gas Networks Ireland (GNI) and have completed highly detailed laser scans for nearly 100 sites, both in Ireland and in the UK.

The laser units employed in the execution of these measurement tasks are intrinsically safe in such potentially explosive environments. With a maximum energy per laser pulse of 135nj, these tools produce a minute fraction of the energy required for an ignition. Furthermore, our professional surveyors wear flame retardant and anti-static overalls for added protection.

Comprehensive scans were obtained across the entire perimeter of the sites, with a special focus on the following details:

• Structural frame and cladding

• Position and size of the main structural elements

• Position and size of all secondary steelwork including purlins, sheeting-rails and anti-sag rods

• Position and size of service trays, pipes and fittings suspended from the structure

• Elevations showing the extent of cladding and penetrations/ openings

• Pipe locations and levels including flange positions

• Levels of the perimeter ground beams indicating the position of any cracks

• Position and size of all plinths and other pipe/ plant supports/ maintenance walkways

The below-ground pipework and structures were mapped using ground penetrating radar (GPR) and EML methods within each AGI site. This field data was then post-processed and correlated with existing plan information to produce an accurate underground 3D model of the below-ground infrastructure.

Investment in accurate surveys and models brings tangible benefits to us and to our customers, enabling the production of 3D models and realistic virtual panoramic tours. With this valuable deliverable at their disposal, engineers can minimise expensive site visits, lessen the period of design and improve the overall quality of their work, thereby increasing the certainty of the project.

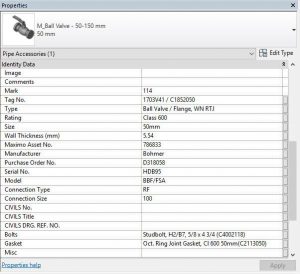

Figure 3 – Asset Information

As consulting surveyors, Murphy Surveys advanced the client’s survey specifications and has been engaging with the engineering teams to achieve a tailored output that benefits both design and construction activities. Computer-aided drawings and 3D models have been the traditional deliverable engineers have used to date. Now parametric Building Information Models are the logical evolution, the building blocks for design, construction and operation tasks. BIM is now regarded as the bespoke graphical output that enables the sharing of project and asset information. Our experienced team of surveyors, engineers and BIM technicians can deliver a precise registry of assets, including detailed 3D geometry, model, serial number and operating manuals.

Murphy Surveys provide a collaborative Common Data Environment, where surveyed information is shared and accessible to all project members, simplifying the use of survey data in multiple tasks of the design process:

• Clash detection analysis

• Management, coordination and validation of models

• Setting-out, supporting BIM to field tasks